Think of an environment where every movement is made by the robots effortlessly, the inventory needs are fulfilled with the help of perfect AI algorithms, and the cloud-based system seamlessly coordinates every order. It is not some kind of a sophisticated vision that is still years away from reality but the new age in warehouse management. As robotics and artificial intelligence advancements increase, warehouses become tech-savvy centres that are gradually revolutionizing the logistics for value-added resellers (VARs).

As solution providers, it is not an option for VARs but a necessity to set their eyes ahead of these trends. So, let’s look at the details of robotics and AI and their impact on the future of warehouse management and unlocking further opportunities.

Stats:

- On average, robotics in warehouses are expected to deliver a 30% improvement by 2026.

- Another application of modern AI solutions is that an AI-driven inventory management system can decrease error rates by 50%.

- The global market for warehouse management systems is expected to reach $6.1 billion by 2026.

What is the Future of Warehouse Management, and How Will Robotics and AI Shape It?

Automate, Intelligent and future-proof are the keywords for the warehouse management system in the coming years. Robotics and AI are no longer a luxury for any organization; they are necessities for warehouses all around the globe. They bring drastic changes; They can solve issues ranging from lack of workers, productivity, and instability of consumers’ demands.

1. Robotics: Enhancing Efficiency

From self-driving to self-navigating, small robots can handle pick and pack services, and collaborative robots (cobots) work side by side-with human employees. Robotics is changing operational models. These machines are designed to work at improved speed and Efficiency while exercising dexterity on repetitive tasks like picking items and sorting boxes. Since robots do not need rest, they cut input-measuring time and boost output by comparing a large number of samples in a very short time.

For example, advanced sensor-fitted AMRs move through a warehouse floor on their own without any direct supervision by a human operator. These robots not only increase Efficiency but also reduce the effects of human interference on the system, making them an important component of the future of warehouse management systems.

2. AI: The Brain Behind the Operations

Artificial intelligence empowers warehouses to intervene and make decisions based on the available data. They use past and current data to predict future demand patterns, manage requisite stock, and control delivery cycles. Another advantage of AI adopted by businesses is that it helps to make accurate predictions on the stock to be stocked or the stock to be ordered so that there is none left in the storeroom.

On another level, AI is central in sophisticated inventory management systems as it can also perform features such as layouts or trends of re-stocking plans. This is of great benefit for VARs as well, as they receive faster, more intelligent, and more reliable operations across the board that can quickly and seamlessly grow as needed.

Key Benefits of Robotics and AI in Warehouse Management:

- Increased Efficiency and accuracy.

- Reduced operational costs.

- Enhanced scalability and flexibility.

- Improved worker safety through automation of hazardous tasks.

How Can the Best Warehouse Management Software Improve Your Operations?

Choosing the best warehouse management software (WMS) is crucial for businesses expecting to follow the industry’s change and growth rate. However, what differentiates the best WMS apart from the rest?

1. Seamless Integration

The most suitable WMS software is one that is compatible with other systems, such as cloud-based order management systems and order management solutions. This makes it possible for businesses to streamline their operations in one platform, hence compounding various processes into one smooth operation with real-time visibility of the supply chain.

2. Optimized Pick and Pack Solutions

Contemporary WMS integrates features such as pick and pack solutions, which are used in the order fulfilment process. Through efficient algorithms for picking routes and packing, businesses can already fulfil orders faster and more accurately.

3. Real-Time Insights

WMS offer real-time information regarding the stock status, order status and general performance of the system. This means that managers will be able to decide on the go by having proper information on demand or supply chain disruptions.

Benefits of Implementing the Best Warehouse Management Software:

- Improved order accuracy and fulfilment speed.

- Enhanced inventory control and optimization.

- Better resource allocation and cost management.

- Scalable solutions for growing businesses.

What Are the Key Trends in Order Fulfilment Software for VARs?

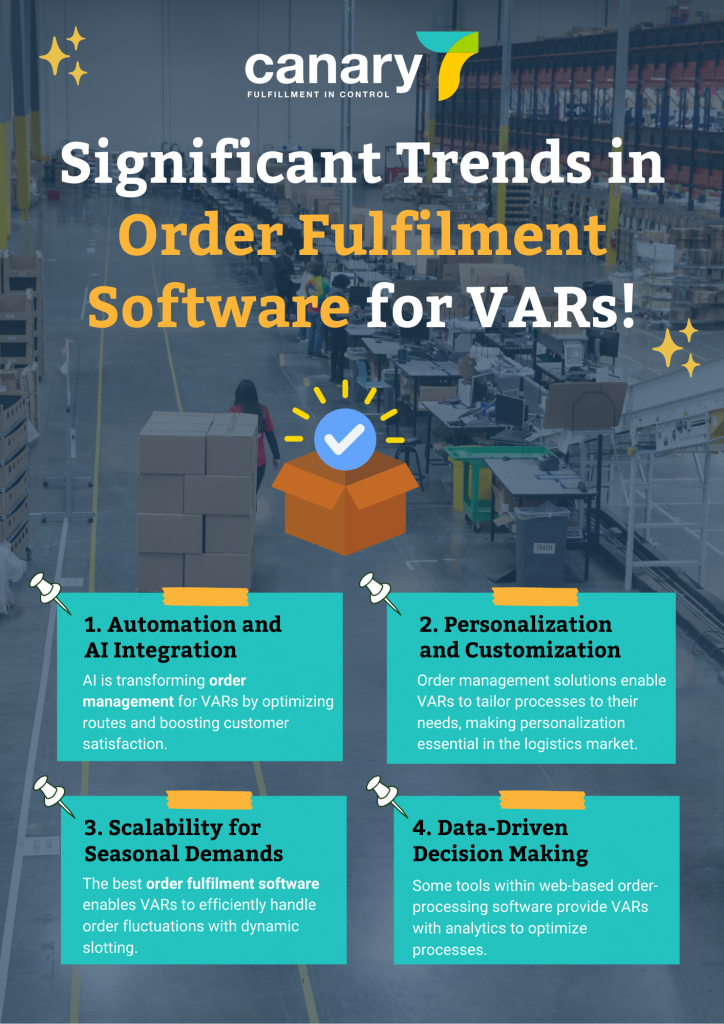

For VARs, order fulfilment software is the backbone of their operations. As customer expectations continue to rise, the software’s capabilities are evolving to meet these demands. Here are the key trends shaping the future of order management software:

1. Automation and AI Integration

With the infusion of AI into order management system software, the kind of order management that VARs carry out is changing. Customers’ preferences can also be analyzed using AI, delivery routes will be the best, and even communication with suppliers can be carried out with the help of artificial intelligence. Effective order processing leads to quicker cycle times in the processing of orders as well as increased consumer satisfaction.

2. Personalization and Customization

Current order management solutions allow VARs to configure the processes according to their organization’s requirements. Personalization has become increasingly critical in the highly competitive logistics and transportation market, from individual packing slips to an individual approach to shipping.

3. Scalability for Seasonal Demands

The best order fulfilment software should also allow VARs to operate at their optimal levels when there is a fluctuating volume in the number of orders being placed. Dynamic slotting and automated replenishment are other valuable tools that enhance Efficiency and control during seasons of elevated demand.

4. Data-Driven Decision Making

Some of these tools are subscribed to and embedded within web-based order-processing software. They deliver analytics to the VARs. Such information helps them to find constraints, optimize processes and upgrade organizational performance.

How Do Cloud-Based Order Management Systems Transform Inventory Management?

Since the adoption of cloud-based order management systems has emerged, the way companies handle inventory and orders has changed. These systems are highly flexible, easy to access and centralized, which makes them immensely valuable to VARs.

1. Real-Time Visibility

With a cloud-based order management system, businesses gain real-time visibility into inventory levels, order statuses, and shipment tracking. This ensures that managers can proactively address issues and optimize operations.

2. Collaboration and Integration

Cloud technology enables seamless integration with other systems, such as inventory management systems and warehouse control software. This fosters collaboration across departments, ensuring that everyone has access to the same up-to-date information.

3. Cost Efficiency

By eliminating the need for on-premises infrastructure, cloud-based order management systems reduce operational costs. They also allow businesses to scale their operations without incurring significant capital expenditures.

Benefits of Cloud-Based Order Management Systems:

- Enhanced flexibility and scalability.

- Reduced IT infrastructure costs.

- Improved collaboration and communication.

- Real-time data access and analytics.

Final Thoughts:

When looking at the future of warehouse management, robotics and AI are considered to be at the centre of this process. To VARs, they represent untold potential to optimize, streamline, and improve the quality and flexibility of business processes. With the best warehouse management software at the corner, utilizing order management strategies and investing in cloud-based order management solutions, companies have the upper hand in a growingly competitive environment.

At Canary7, we understand the critical role technology plays in shaping the logistics landscape. Let us guide you in navigating this exciting journey, ensuring your operations are primed for success in the era of robotics and AI.

Namrata Chawla

Author

UPDATED ON: 21st Jan 2025

Namrata Chawla, a professional writer, crafts compelling weblog content on warehouse management, inventory control, logistics, and beyond. With a wealth of experience in this niche, she's dedicated to delivering unique, informative, and top-tier posts. Her commitment to exploration ensures fresh perspectives in each insightful blog post.

Subscribe to get latest posts straight in your inbox.